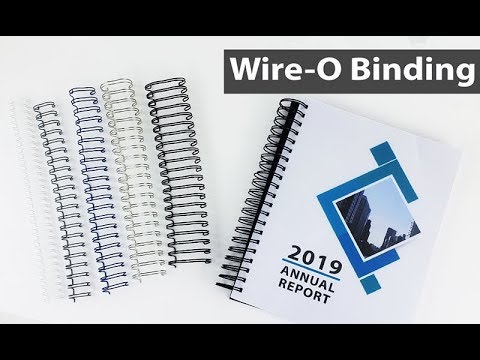

White 3:1 Wire-O Twin-Loop Binding Spool

- 3:1 Pitch sizes available from 5/8" up to 1-1/4"

- Continuous wire spine on a spool works with many popular automatic wire binding machines

- Work with any binding edge size - just cut the spool to the length you need

- Offers a professional wire book binding finish

- Oversize / Truck shipping

$80.30

Regular: $154.99

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

Overview

Specifications

| Item # | WIREOSPOOLSWH31-GRP |

|---|---|

| Manufacturer | James Burn |

| Binding Style | Wire-O Binding |

| Sheet Size | Compatible with Multiple Sheet Sizes |

| Pitch | 3:1 Pitch (2 Loops per Inch) |

| Diameter | Choose from 5/8" - 1-1/4" |

| Sheet Capacity | Varies Depending on Size (See Chart Below) |

| Recommended Book Thickness | Varies Depending on Size (See Chart Below) |

| Quantity | 1 Spool |

Description

For bulk wire binding in your large print or binding shop, a Wire-O Twin-Loop Binding Spool may be the perfect solution. We offer only the highest quality double-o wires from James Burn, available in a huge selection of sizes and colors to fit your exact needs. Whether you need small 3:1 pitch wires or large 2:1 pitch wires, we stock the wire spools that you need.

Books bound with wire spools lay flat when open and offer a full 360° flip capability, so you can flip the pages over all the way until they touch the back. This makes them a popular choice for calendars, especially when paired with our easy-to-use metal calendar hangers.

A Wire-O spool is measured by a loop count, and the loop count will vary depending on the wire diameter selected. For example, the smallest 1/4" wires feature 90,000 loops on one spool, whereas the largest 1-1/4" wires feature 2,900 loops. You can use the chart below to see the different loop counts per spool and help determine the best wire size for your particular needs, based either on an approximate sheet capacity or approximate book thickness.

Wire-O Binding Capacity Chart:

Simple steps to get the proper fit for twin loop wire binding.

- Take the book being bound and lay it flat on a table

- Don't compress the paper and measure the thickness of the binding edge

- Take the measurement and add 1/8" - that will be the size of the binding element

| Wire Diameter | Pitch (Holes per Inch) | Sheet Capacity¹ | Book Thickness | Loops / Spool |

|---|---|---|---|---|

| 1/4" | 3:1 | 11-25 Sheets | 1/8" | 90,000 |

| 5/16" | 3:1 | 26-45 Sheets | 3/16" | 66,000 |

| 3/8" | 3:1 | 46-65 Sheets | 1/4" | 47,000 |

| 7/16" | 3:1 | 66-80 Sheets | 5/16" | 32,000 |

| 1/2" | 3:1 | 81-100 Sheets | 3/8" | 26,750 |

| 9/16" | 3:1 | 101-120 Sheets | 7/16" | 22,000 |

| 5/8" | 2:1 | 121-145 Sheets | 1/2" | 11,000 |

| 3/4" | 2:1 | 146-165 Sheets | 5/8" | 8,000 |

| 7/8" | 2:1 | 166-185 Sheets | 3/4" | 5,150 or 6,100 |

| 1" | 2:1 | 186-210 Sheets | 7/8" | 4,600 |

| 1 ⅛" | 2:1 | 211-235 Sheets | 1" | 4,000 |

| 1 ¼" | 2:1 | 236-260 Sheets | 1 ⅛" | 2,900 |

The premier choice among professionals of all kinds, Wire-O binding offers a clean, finished look that can be found on journals, notebooks, presentations, guides, and so much more. The attractive metal finish looks expensive when compared to plastic bindings, so you are sure to impress your customers. They are built to work with a large variety of industrial and automatic binding machines on the market today. When paired with these machines, twin loop spools offer a very fast and convenient way to bind large quantities of wire-bound books.

¹ Sheet capacity is an approximation using 20 lb. bond copy paper. It will vary depending on the stock used.

For bulk wire binding in your large print or binding shop, buy Black 2:1 Wire-O Twin-Loop Binding Spool at Binding101. We offer only the highest quality double-o wires from James Burn, available in a huge selection of sizes and colors to fit your exact needs. Whether you need small 3:1 pitch wires or large 2:1 pitch wires, we stock the wire spools that you need.

The premier choice among professionals of all kinds, Wire-O binding offers a clean finished look that can be found on journals, notebooks, presentations, guides, and so much more. The attractive metal finish looks expensive when compared to plastic bindings, so you are sure to impress your customers. They are built to work with a large variety of industrial and automatic binding machines on the market today. When paired with these machines, twin loop spools offer a very fast and convenient way to bind large quantities of wire bound books.

Choose from many beautiful metal colors, including black, white, silver, pewter, blue, green, red, and more. Books bound with wire spools lay flat when open, and offer a full 360° flip capability, so you can flip the pages over all the way until they touch the back. This makes them a popular choice for calendars, especially when paired with our easy-to-use metal calendar hangers.

Wire-O spool is measured by a loop count, and the loop count will vary depending on the wire diameter selected. For example, the smallest 1/4" wires feature 90,000 loops on one spool, whereas the largest 1 ¼" wires feature 2,900 loops. You can use the chart below to not only see the different loop counts per spool, but also to help determine the best diameter size for your particular needs, based either on an approximate sheet capacity or approximate book thickness.

Wire-O Binding Capacity Chart:

Simple steps to get the proper fit for twin loop wire binding.

- Take the book being bound and lay it flat on a table

- Don't compress the paper and measure the thickness of the binding edge

- Take the measurement and add 1/8" - that will be the size of the binding element

* Note: the capacities listed below are approximations, determined using standard 20 lb. bond copy paper; the actual sheet capacity will vary depending on the materials being bound.

| Wire Diameter | Pitch (Holes per Inch) | Sheet Capacity* | Book Thickness | Loops / Spool |

|---|---|---|---|---|

| 1/4" | 3:1 | 11-25 Sheets | 1/8" | 90,000 |

| 5/16" | 3:1 | 26-45 Sheets | 3/16" | 60,000 |

| 3/8" | 3:1 | 46-65 Sheets | 1/4" | 47,000 |

| 7/16" | 3:1 | 66-80 Sheets | 5/16" | 32,000 |

| 1/2" | 3:1 | 81-100 Sheets | 3/8" | 26,750 |

| 9/16" | 3:1 | 101-120 Sheets | 7/16" | 22,000 |

| 5/8" | 2:1 | 121-145 Sheets | 1/2" | 11,000 |

| 3/4" | 2:1 | 146-165 Sheets | 5/8" | 8,150 |

| 7/8" | 2:1 | 166-185 Sheets | 3/4" | 5,150 or 6,100 |

| 1" | 2:1 | 186-210 Sheets | 7/8" | 4,600 |

| 1 ⅛" | 2:1 | 211-235 Sheets | 1" | 4,000 |

| 1 ¼" | 2:1 | 236-260 Sheets | 1 ⅛" | 2,900 |

¹ Sheet capacity is an approximation using 20 lb. bond copy paper. Will vary depending on stock used.

Videos

Wire-O Binding Supplies Overview PLUS Wire Bind Pros and Cons

Video Transcript: Twin loop Wire-O binding is one of the most popular ways to punch-and-bind professional presentations and reports. They offer a clean, high-class appeal that is unmatched by any other traditional binding method.

Wire-O binding spines come in either a 3:1 or a 2:1 pitch. This pitch ratio refers to the number of holes punched per inch along a binding edge. 3:1 pitch creates 32 holes along an 11” letter si... Read More

Video Transcript: Twin loop Wire-O binding is one of the most popular ways to punch-and-bind professional presentations and reports. They offer a clean, high-class appeal that is unmatched by any other traditional binding method.

Wire-O binding spines come in either a 3:1 or a 2:1 pitch. This pitch ratio refers to the number of holes punched per inch along a binding edge. 3:1 pitch creates 32 holes along an 11” letter size edge. It is used for thinner books from ¼” to 9/16” wire diameters, or about a 120 page document. 2:1 pitch punches 21 holes along that same edge, and is used primarily for thicker books from 5/8” to 1-1/4” wires, or about a 260 page document. We also offer special smaller 2:1 wire binders in all of the 3:1 pitch sizes.

Our cut wire binding supplies are the perfect length for a letter size document, while our spooled wire can be cut to any size you need, or used on your more automated binding equipment. We can also custom-cut wires to nearly any length that you need.

Available in a large variety of professional colors, twin loop wire binders make a great financial report, client presentation, or proposal.

And wire binding has some advantages over the other punch-and-bind methods out there: For 1, which we already mentioned-- they are professional! The metal wire looks nicer to most customers than other plastic options. #2: The books will lay flat, without the need to hold them open. #3: The book pages can turn a full 360°. And #4: They have perfect registration, which means that the pages remain aligned and square, even when turned over. With all those great features, it is no wonder why Wire-O is one of the most popular ways to bind.

But there are some things to consider before you choose wire-o as your binding method of choice: #1: How often will the books be handled? Metal wire can bend, and may not be able to bend back and look nice again, so they are better for temporarily-handled books. #2: Will you need to edit the book? Wire bindings cannot be re-opened or edited. So if you find an error or need to add or remove a page from your document, you need to cut the wire off and re-bind it with a new spine. #3: Does a bulky spine bother you? Punch-and-binds will all have a bit of a bulk on the binding edge from the spine itself, so if you need something more seamless, consider thermal binding or tape binding instead.

#4: What book sizes will you be binding? Because there are two hole patterns for wire, and many machines that will only punch one of the two, you need to determine what size books you plan to bind before you buy your machine. If you are not sure, you can always get a duo-punch that will handle both.

With our selection of twin loop Wire-O binding supplies, professionally-bound presentations of all kinds are simple, affordable, and right at your fingertips.

So head on over to Binding101.com for more information, or to get started today. And if you liked this video, please give it a thumbs up, and subscribe for more.